Product-centric Origins: Made at MIT

Location

Massachusetts Institute of Technology (MIT), MechE and The Media Lab

2008-2015

Tags

Laser Cutter; 3D Printing; CNC Machining; Electronics Production and Coding; Molding and Casting; Team-based Decision-Making

Background

My first taste of being a Maker and Product Designer were in the halls of MIT. This is where I first learned to listen to users, filter for good ideas, inspire teams, and bring functional prototypes to life, all in an extremely pressured environment.

A functioning award-winning prototype in just 3 months

One of my first experiences on our 18-person product design team was to stand up against a vote of 17 to 1 to convince team members that the better product to pursue was, indeed, a helmet vending machine and not a carry-on suitcase with an embedded chair because of market size, technology readiness, and most importantly, user need. Once convinced, we were on our way to making HelmetHub, the first of its kind to dispense (and later, accept returned) helmets for users of public bike share programs. I sketched, I CADded, I machined, and I grew proud of our accomplishment. HelmetHub went on to receive a patent and be admitted to the MassChallenge startup accelerator.

Our functioning prototype sitting at a bicycle docking station, ready to dispense helmets to the next customer. |  Early sketches for helmet dispensing mechanisms offered in pin ups during design reviews. |  Early sketches that allowed for dispense and return of helmets offered during early ideation sessions. |

|---|---|---|

An early prototype demonstrating functioning mechanisms for our Technical Review. Significant efforts were seen by our team of 18 to reach these milestones. |  A final rendering of HelmetHub, designed to take up just one spot on a bicycle dock station, granting public bike sharing customers access to safety on their heads. |

Life-saving Designs for Women in Totogalpa, Nicaragua

I traveled with my design team to the rural fields of Totogalpa, Nicaragua on a mission to help the women entrepreneurs achieve their business goals. Thanks to my native Spanish, I quickly became their trusted representative, and they were able to let their guard down and conduct business as usual as if we weren't even there. This was important because it allowed us to observe their process unfiltered, and I was recording when they got one small coordinated move wrong and almost sent a burning oil drum tumbling into the field— very dangerous stuff. With this insight I took to the drawing board and developed 3 options for them to do the same process in a safer, more reliable way. We sent over some prototype sketches, they tried them out, and they quickly adopted a much safer protocol for their business. Success!

Detailing out the parts of the process that are improved thanks to our team's new designs. |  A team member secures the barrel shut to begin the anaerobic burn, this time without having to tip over the burning barrel. |  The "Solar Woman" entrepreneur prepares the oil barrel with dry agrowaste to burn into charcoal briquettes they'll later use for fuel. |

|---|---|---|

DANGER! DANGER! A screenshot of my recording that captured the original and dangerous process of dismounting the burning oil barrel. Our improved designs removed the need to dismount the barrel, making the process safer and more reliable for the women. |

Cutting Actuators

I challenged myself to adapt a 3D milling machine into a cutter that used off the shelf exacto knives such that it could oscillate at high frequencies and cut through material like cardboard and foam core, thus shortcutting (ha!) the need for a laser cutter. I designed the apparatus, prototyped with found parts, then laser cut and 3D printed features and continued iterating until we had a working prototype. Ultimately I learned of the challenges of cutting curves and left with a greater appreciation for laser cutters everywhere.

|  |  |

|---|---|---|

|

Fashion Forward 3D Printing

As part of my Media Lab class, How to Make (almost) Anything, I designed and 3D printed a ring with a game. I started with the conept of the famous maze puzzles with steel balls from our childhood, added a theme of MIT's 1st Mini-Maker Faire (that I was organizing the very week I was making these) and what resulted was fabulous souvenirs for my Organizing Team. The prototypes started as 3D printed rings on the Objet and ZCorp printers, but more my (relatively) mass-scale production, I moved to a laser-cutting friendly design.

|  |  |

|---|---|---|

|  |  |

Computer Numerically Controlled Home Decor

For the weekly project in my Media Lab class, How to Make (almost) Anything, the assignment was to 'Make Something Big'. Morris and I thought of a clever way to disguise all the hanging cables under our TV whilst making an art piece that was engaging and provocative. I used a maze-making software to overlay a maze onto the MIT logo, a symbol of the winding labrynth it is to learn at the 'tute. The twists and turns are appreciated at the lower depths of the work, and it's only from a wider perspective that one can re-focus and appreciate the bigger MIT. I designed the cad in Illustrator, processed it in MasterCAM, and machined it on the magical Onsrud in the woodshop.

|  |  |

|---|---|---|

|

Miscellaneous Making around the 'tute

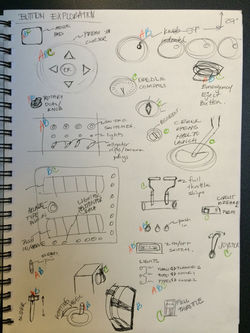

Sketching button options for the interface to our sci-fi adventure game. |  I illustrated what this interface might look like to give my team project direction: tech-y, futuristic, powerful, and sophisticated. |  I prototyped some buttons and brought them to life in foam core and blue foam and other found parts from the lab. Here I was prototyping form over function. |

|---|---|---|

A group of girls enchanted with our electronics display at the Maker Faire. I was a founding member for the fair and it was a treat to see so many community members leave so inspired! |  A proud team of founding members for MIT's 1st Mini Maker Faire. I secured key partnerships with MIT staff to make this come to life, and we hosted over 1000 visitors and over 60 exhibitors. |  In an exploration of design across scales, I collaborated with 2 others in this energy analysis that tracked: where's your energy right now and how would your selfie say that? |

As part of molding and casting week, I set out to create visually telling ice trays where each number mapped to the number of shot-units in that ice piece. The idea was to more accurately serve drinks that transparently reported how much alcohol they contained. Then I re-learned about alcohol's freezing temperature. Womp womp. |  My grand marketing campaign to raise funds for a maker space: bring the machines to life! I laser cut life size machines and placed an exaggeratedly large price tag on them and encouraged visiting alumni to Venmo that exact amount right then and there and they could see exactly where their contribution was going. It was the most successful fundraising campaign in recent history. |

Process Highlights

-

In the Media Lab class, How to Make (almost) Anything, and then, How to Make Something that Makes almost Anything, I learned a new digital fabrication tool each week and produced something to show for it. I learned to be self-resilient and build alongside my peers in a system Prof. Gershenfeld called “Ask three then me”.

-

For my senior Mechanical Engineering capstone, my 18-person team and I built a helmet vending machine for public bicycle share users that went on to become a MassChallenge Accelerator finalist and start-up (Patent Application 14/322613).

-

In my first international adventure with D-Lab, I observed how Nicaraguan women entrepreneurs struggled with a life-threatening mechanism when burning their oil barrels of agro waste, which led me to co-create a safer, more resilient tool for their process that was widely adopted and preferred.

Results

Making is at my core as a designer. Understanding how something is made helps me understand how the world works, and with it how product teams can organize under realistic expectations of work. The mindsets of iteration, proving something might work, treating peers as partners, making better mistakes, and looking for the next opportunity, are embedded in my DNA as a problem-solver. After years of making, I saw a need for celebrating the MIT community and was a founding member of the first ever MIT Mini Maker Faire on campus, adding more logistical and operational expertise to my repertoire. I also created an alumni donation campaign and founded a thriving makerspace inside the the residence I advise.